Resistance spot welding

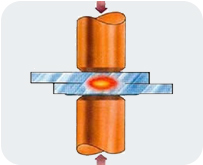

Spot welding allows you to connect to the tab sheets in a suitably spaced points. Sheets are pressed each other with help of conductive electrodes claw. At the point of compression of the material sheet by the passage of current warms up and combined together.

Spot welding allows you to connect to the tab sheets in a suitably spaced points. Sheets are pressed each other with help of conductive electrodes claw. At the point of compression of the material sheet by the passage of current warms up and combined together.

Spot welding is the most common method of resistance welding. Its most common use is to combine elements made of carbon steel and alloy steel , nickel , titanium and their alloys and copper alloys and aluminum.

Welded material thickness depends on the type of material; in the case of carbon steel with a carbon content of 0.25 % maximum sealing thickness not exceeding 20 mm , in the case of aluminum and its alloys 5 mm. Yield spot welding is very high , and for plates with a thickness of 0.8-1.0 mm welding comes to 2000 per hour using single point welding life and welds to 10,000 in the case of multi-electrode welding . Spot welding ensure the implementation of the links with high strength.

PARAMETRY ZGRZEWANIA ISKROWEGO:

- current in kA- pressure strenght in kN

- welding current flow time in sec

- work dimensions in the electrodes in mm

clients

Manufacturers of fencing panels

A large number of customers of our machines are manufacturers of modern and practical modular fences...

Manufacturers of gabions

New, interesting direction of development of small architectural elements, are gabions...

Manufacturers of welded screens

Screens are manufactured by using resistance welding of profiles with crosspieces or longitudinal wires with cross...Read more