Friction welding

Friction welding is a process in which the heat necessary for the implementation of a permanent connection originated from the direct conversion of mechanical energy into heat energy through friction in the interface between the welded objects.

Friction welding is a process in which the heat necessary for the implementation of a permanent connection originated from the direct conversion of mechanical energy into heat energy through friction in the interface between the welded objects.

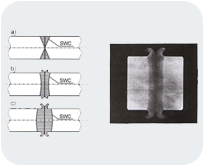

GENERAL COURSE OF FRICTION WELDING:

- driving one of welded objects to rotary speed n

- exerting friction pressure Pt by pushing the second welded object

- eating the connector by converting the kinetic energy into heat of friction

- stop rotation and exerting pressure of swelling Ps

The process of heating welded elements runs in such a way, that at first external surfaces are heated (which facilitates the squeezing of impurities), and then the heat flows to inside and spread out evenly in the area in front so that a weld.

PARAMETERS OF FRICTION WELDING:

- rotational speed

- friction pressure

- time of friction

- swelling pressure

- swelling time

BY THIS METHOD CAN BE WELDED:

- carbon steels

- tool steels

- corrosion resistant steels

- copper

- aluminum

- nickel alloys

- copper alloys

- titanium

- zirconium

- unlike connections

MAIN ADVANTAGES OF FRICTION WELDING:

- high quality connectors, due to controlled thermo-mechanical treatment occurring during the welding process- the possibility of combining the material that differ significantly in physical properties

- the possibility of combining objects with different shapes and sizes; there is usually limited length of only one of the welded object

- high performance welding, up to 600 connections/h

- uniform network load and low energy consumption

- high reproducibility of the welding effects and the ability to control and quality control during the welding cycle

- ease of use devices and ease of automation

clients

Manufacturers of fencing panels

A large number of customers of our machines are manufacturers of modern and practical modular fences...

Manufacturers of gabions

New, interesting direction of development of small architectural elements, are gabions...

Manufacturers of welded screens

Screens are manufactured by using resistance welding of profiles with crosspieces or longitudinal wires with cross...Read more