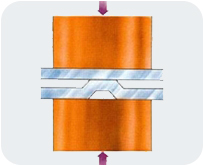

Resistance projection welding

The weld is formed at the point of contact, specially shaped for the working material. For example, the contact point (hump) may be a bulge or ring or elongated projections technology. Connecting elements can be carried out simultaneously in several points. Sufficiently large electrodes include all the points that have to be welded in one operation. Butt or folded joints are created.

The weld is formed at the point of contact, specially shaped for the working material. For example, the contact point (hump) may be a bulge or ring or elongated projections technology. Connecting elements can be carried out simultaneously in several points. Sufficiently large electrodes include all the points that have to be welded in one operation. Butt or folded joints are created.

APPLICATION EXAMPLES:

- welding sheet metal screws and nuts designed in this respect and available on the market.- projection welding rod-shaped elements, such as screws or fasteners (bolts).

- projection welding of the tubular elements (T and cross connectors), and the pins, cams and ribbing.

- welding of cross wires

clients

Manufacturers of fencing panels

A large number of customers of our machines are manufacturers of modern and practical modular fences...

Manufacturers of gabions

New, interesting direction of development of small architectural elements, are gabions...

Manufacturers of welded screens

Screens are manufactured by using resistance welding of profiles with crosspieces or longitudinal wires with cross...Read more