Automated production lines

Automated production lines, produced by WELD welding technology Sp. z o.o., are designed for the efficient production of reinforcing mat, a wide range of meshes, grids and fencing panels.

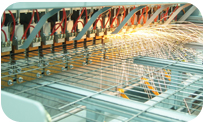

Depending on the destination, produced lines use different solutions. Lines for the production of fencing panels or other gratings composed of thick rods are based on welding straightened and cut to length rods. Rods can be prepared off-line and loaded manually or straightened, trimmed and included into the welding process automatically.

Lines for welding reinforcement mats, rolling meshes, or other meshes composed of thin wires, are adapted to work in a system of continuous welding and cutting to size. In this case, the longitudinal wires are unwound directly from the discs and straightened up to date.

Depending on the expectations of the customer, the offer may relate to:

- line panels 'P', which, thanks to the press built - in string technology, enables performing of stiffening inflections

- line for simple panels composed of three layers of rods with diameters of 6 - 5 - 6 and 8 - 6 - 8 mm.

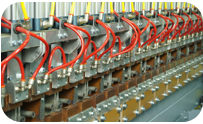

Production line for panels straight, characterized by a specially designed sealing assemblies and wire feeders, allowing stacking three layers of rods . The offer takes into account the statement permitting for production of both panels simple and bended . On client request, the line can be equipped with a device for laying of welded mesh on a pallet, ready for dispatch . Work of the line does not require the involvement of service, the production process runs automatically. Operating activities come down to refill used wire and disposal of the finished product. The welder’s design provides for changing the diameter of welding wire used and changing loops spacing in both directions. Vapor control system is a microprocessor controller and touch panel. The welder’s energetic circuit uses toroidal transformers with high efficiency, which significantly reduces electricity consumption.

Technical Characteristics

| o.n. | data | units | value |

|---|---|---|---|

| 1 | Diameter of welded wire | mm | 2-12* |

| 2 | Spacing of longitudinal wires | mm | 30-200 |

| 3 | Spacing of cross wires | - | dowolny |

| 4 | Width of welded mesh | mm | do 2500 |

| 5 | Lenght of welded mesh | mm | do 2500 |

| 6 | Time of one line welding + pass | sek | 2-3 |

| 7 | Production efficiency | szt/h | 40 –70** |

| 8 | Voltage of Power supply | V | 400 |

| 9 | Type of pressure | - | pneumatyczny |

| 10 | Type of cooling | - | wodny |

| 11 | Dimensions

- height - width - lenght (depending on combination) |

mm mm mm |

1600 3500 9000 - 18000 |

| 12 | Mass | kg | 3000 - 5000 |

* - Parameter set individually

** - Depending on size of panel and energy attachment

Gallery

clients

Manufacturers of fencing panels

A large number of customers of our machines are manufacturers of modern and practical modular fences...

Manufacturers of gabions

New, interesting direction of development of small architectural elements, are gabions...

Manufacturers of welded screens

Screens are manufactured by using resistance welding of profiles with crosspieces or longitudinal wires with cross...Read more